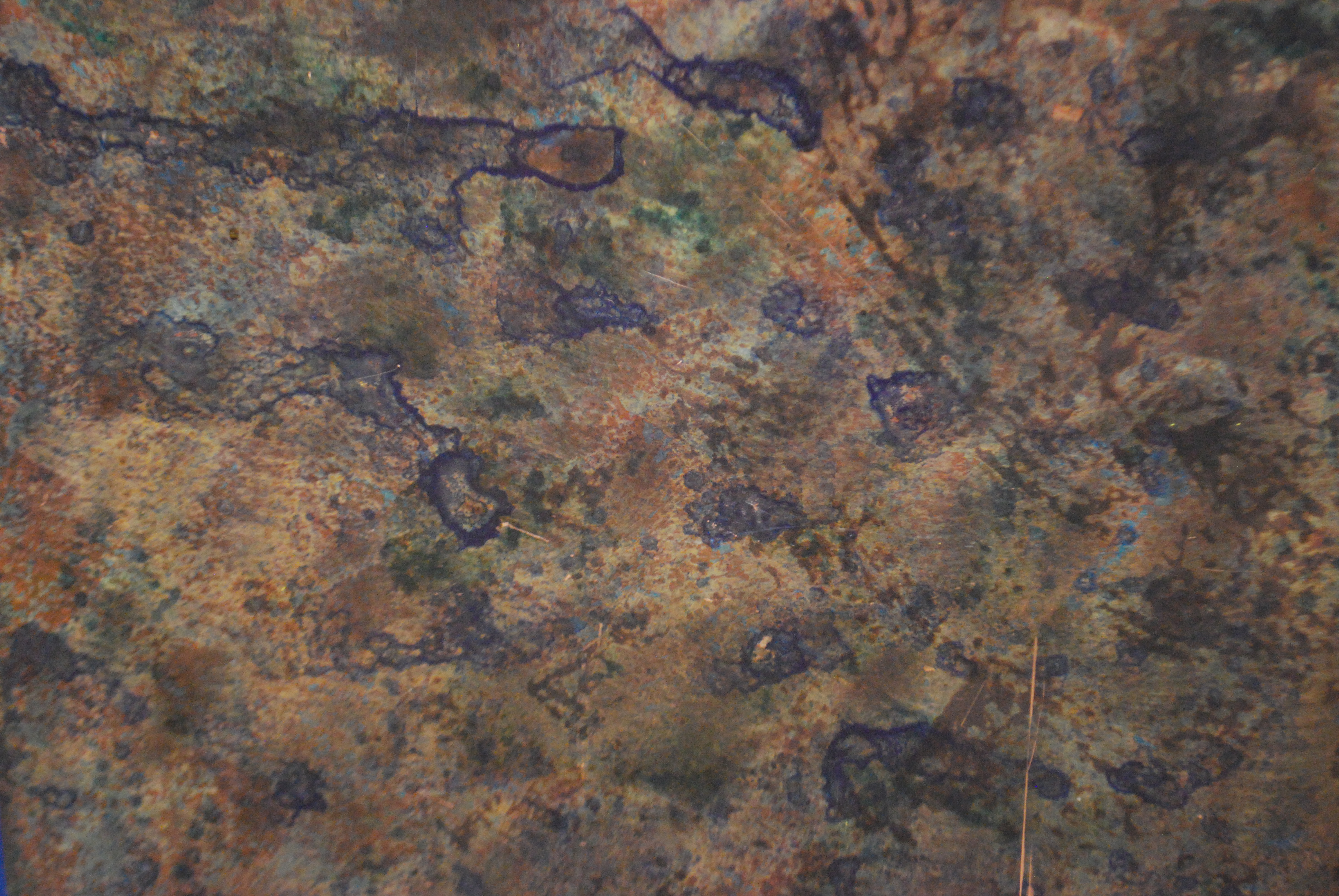

Silver, or one of its alloys, are bright and shiny.271 lbs/in³), wrought iron shares the same density as steel at 7.8 g/cm³ (.282 lbs/in³), and stainless steel of 7.9 g/cm³ (.285 lbs/in³). Iron, or one of its alloys, which are relatively lustrous and gray in hue.Deoxidized copper has a density of 8.9 g/cm³ (.322 lbs/in³), copper nickel 8.8 g/cm³ (.318 lbs/in³), navy brass 8.6 g/cm³ (.311 lbs/in³), and silicon bronze of 8.7 g/cm³ (.314 lbs/in³). Copper, or one of its alloys, which are usually reddish in color.It is a light, common metal that shares a density of 2.7 g/cm³ (. Aluminum, or one of its alloys, which are often silvery-white.Calculate the density of your metal to help determine if it is one of the following common metals/alloys: Each one has unique properties, which means some chemicals will work and others won't. Some metals are made up of a single component, like gold and copper, but others are combinations, called alloys, like brass and steel. Let dry completely, solvent wipe and apply Everbrite Coating to seal and protect your rusted metal.Determine the composition of your metal. Make sure to neutralize the acid and rinse well. If you prefer a faster method to rust metal, we have Instant Rust Accelerator available that creates real rust on iron-based metals. Do this several times a day and your metal will get rusty. Using a separate sprayer, apply the hydrogen peroxide over the vinegar right away. (Any kind will do - the cheaper the better). One way to rust metal on purpose with household items is to spray vinegar and hydrogen peroxide separately on the metal. You can sandblast the metal or use Scotchbrite pads to clean the surface. This is not only dangerous to your health but can damage other items as well.įirst, make sure the metal is clean, remove all mill scale and any oil or dirt. How can I rust metal on purpose? Some people recommend rusting metal with dangerous chemicals like muriatic acid, sulphuric acid or combinations of chemicals. Everbrite™ will seal the metal and will look great for years and can be maintained indefinitely. Spray a light coat of water over the plate, then place salt where you want 'rust.' In areas where you want no top coat color, make sure to completely pile enough salt to cover any gaps. On raw steel or rusted metal, 3 to 4 coats are recommended because the metal is very porous. On most metals, two coats of Everbrite™ Clear Protective Coating are recommended. Give the surface a more finished, purposeful look.Įxcellent adhesion on naturally or artificially rusted surfaces.Įverbrite™ is self-annealing and will blend to itself to create complete protection.Įasy to apply - wipe, roll, paint or spray on completely clean and dry rusted metal.Įverbrite™ is available in a Clear finish and a Satin finishĮverbrite™ will seal moisture out of rusted metal to help prevent further corrosion and will prevent rust stains. Helps to extend the life of the steel by sealing out moisture that can cause further corrosion. Rusty drips on other substrates can ruin the look of a building.Įliminate transfer of rust to people (hands & clothing). Everbrite Coating provides the following benefits to rusted metal with every application:Įliminate staining of surrounding areas from unsightly runoff and stains.

0 kommentar(er)

0 kommentar(er)